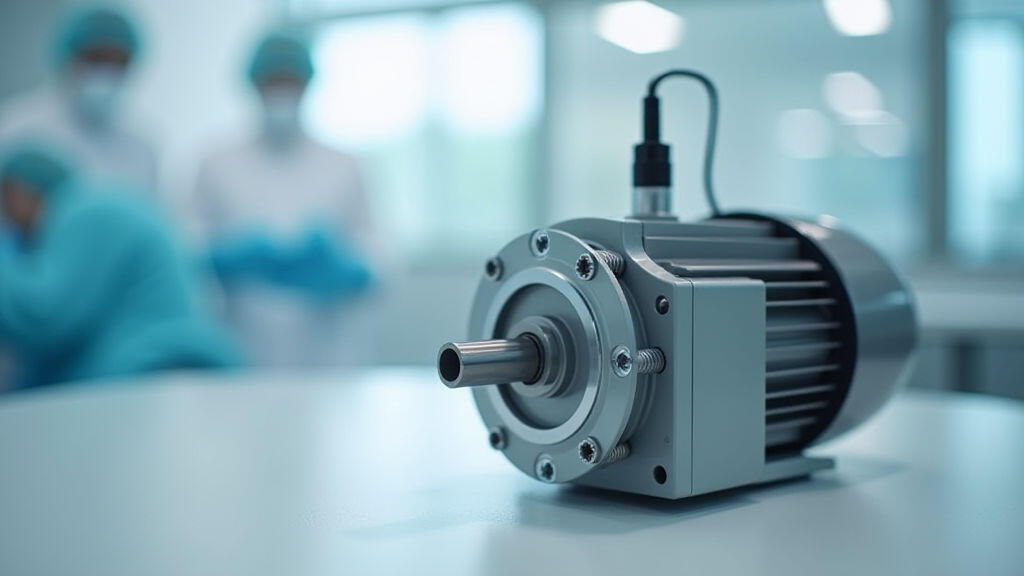

Medical devices such as infusion pumps, robotic surgical arms, and diagnostic imaging systems demand flawless motion control. In this context, the gear motor—an electromechanical component that couples electric power to precise mechanical movement—plays a pivotal role. Selecting the correct gear motor, and accurately calculating its specifications, is not just a routine engineering task; it is the backbone of intelligent manufacturing that ensures reliability, safety, and performance in medical equipment.

At its heart, a gear motor comprises three essential elements: an electric motor (typically AC or DC), a set of gears that alter speed and torque, and a shaft that transmits motion. The electric motor turns the shaft, and the gears adjust the output to match the device’s needs—tight torque for drilling, low speed for an infusion pump, or high precision for a micro‑surgery robot.

While the concept sounds simple, the choice of motor type (brushless vs. brushed, universal vs. dedicated) and gear configuration (gear ratio, material, mounting style) can dramatically influence a product’s durability, thermal characteristics, and noise profile—factors all critical in a sterile medical environment.

In hospitals, equipment must remain functional for weeks or months without frequent maintenance. A properly selected gear motor avoids unpredictable wear, ensuring consistent performance even after repeated sterilization cycles.

Many medical devices rely on sub‑millimeter accuracy. Gyroid helix‑shaped gears or harmonic drives—once selected appropriately—provide smooth, backlash‑free motion that translates into safe drug delivery or precise imaging.

Intelligent manufacturing focuses on energy‑efficient, low‑profile designs. A gear motor that is oversized or mismatched can draw excessive current, generating heat that needs large cooling solutions, which in turn increase size and power consumption.

Regulatory bodies like the FDA or CE require detailed documentation of component selection, including gear motor derivations. A robust calculation process helps manufacturers demonstrate compliance with ISO 13485 and IEC 60601 standards.

Efficiently selecting a gear motor involves a step‑by‑step calculation game. Below are the main stages:

A manufacturing plant recently upgraded its infusion pump line. Engineers needed a gear motor that could roll out 150 µL per second, while also enduring 500 000 injection cycles over its operating life.

Step 1 – Define the Need:

Peak torque: 0.3 Nm; speed: 100 rpm (rotations of the pump capsule).

Step 2 – Motor Choice:

A 24 V BLDC motor was chosen for low noise and high torque density.

Step 3 – Gear Ratio:

A 30:1 gear train was selected, giving an output about 8 rpm at the capsule, suitable for accurate dose delivery.

Step 4 – Verification:

Mechanical simulation showed peak stresses below 20 MPa, well within the safety margin. Thermal analysis predicted a 5°C temperature rise, comfortably within device limits.

The result? A robust, energy‑efficient pump that meets all regulatory requirements and exceeds user expectations for accuracy.

The future of medical equipment manufacturing is increasingly software‑centric. Predictive maintenance algorithms can read motor sensor data (current, vibration) to forecast wear before failure. Moreover, newly emerging micro‑gear motors with piezoelectric actuators promise even finer control, enabling next‑generation surgical robots and implantable drug delivery systems.

By embedding real‑time monitoring and adjustability, the gear motor becomes not just a component but an operational asset—enabling adaptive performance and reducing downtime.

In the intelligent manufacturing of medical equipment, gear motor selection is a critical decision that reverberates across reliability, precision, efficiency, and regulatory compliance. A systematic, calculation‑driven approach ensures that every device delivers safe, accurate performance while remaining cost‑effective and future‑ready.

As medical technology continues to advance, the role of the gear motor—backed by smart analytics and innovative materials—will become ever more central. Manufacturers who master the science and art of gear motor selection will not only keep up with current trends but will also shape the next wave of breakthroughs in patient care.

Leave A Reply

Your email address will not be published. Required fiels are marked